Rectificadora y fresadora de correas de distribución QD150G

El modelo QD150G es un diseño integral para el rectificado de correas de distribución. Permite rectificar la parte trasera y el borde de la correa de distribución e incluye un dispositivo para fresar los dientes de la superficie de la correa.

Ficha Técnica

| Tipo | QD150G |

| Adecuado para | Productos de revestimiento de láminas o correas de PU/caucho |

| Voltaje de trabajo | 380 V trifásico o según solicitud |

| Frecuencia | 50~60HZ |

| Ancho de trabajo | 5-150mm |

| Espesor de la banda de trabajo | 1-20mm (Por favor, infórmenos si necesita procesar una correa más delgada o más gruesa.) |

| Ancho de rectificado | 5-150mm |

| Longitud de trabajo | 1500mm-longitud ilimitada |

| Potencia del motor de rectificado de bordes de banda | 1.5KW |

| Velocidad del husillo | Velocidad ajustable en frecuencia |

| Velocidad del motor de rectificado de bordes de banda | 4500r/min |

| Potencia del motor de rectificado de banda trasera | 1.5KW |

| Velocidad del motor de rectificado de banda trasera | 3500r/min |

| Precisión del fresado de dientes | ±0.2mm |

| Precisión del fresado de dientes | ±0.4mm |

| Estructura de la máquina | Recubrimiento de plástico superficial + tratamiento de galvanoplastia de accesorios |

| Características | Beneficios |

| Una máquina puede realizar 3 tipos de funciones de procesamiento de correa de distribución: rectificado posterior de la correa / rectificado del borde de la correa / fresado de dientes | Operación simple, menor costo de entrada de la máquina, alta precisión. |

| Panel de control digital y mango giratorio con ajuste de alta precisión. |

Precisión del rectificado de cantos y dorso: ±0,2 mm Precisión del fresado de dientes: ±0,4 mm |

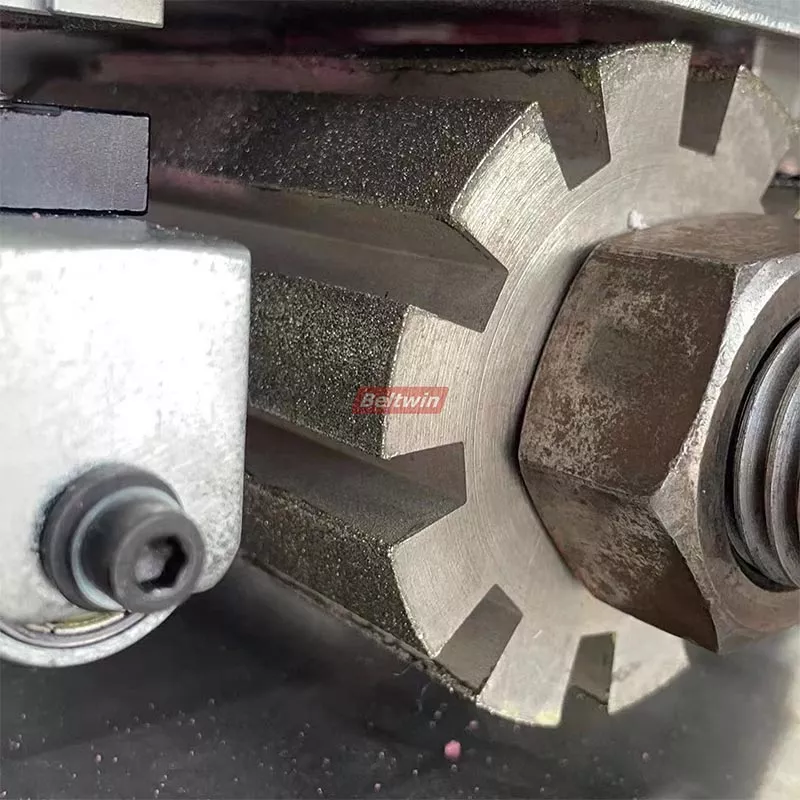

| Equipado con una fresa de alta velocidad y herramientas abrasivas de diamante, se utiliza especialmente para moler diversos materiales pegados. | La herramienta de rectificado es muy duradera y no requiere mantenimiento, la velocidad es de hasta 4500 rpm y la superficie procesada es muy lisa. |

| El tamaño de la herramienta de fresado se puede cambiar | Adecuado para requisitos de fresado longitudinal de varios anchos. |

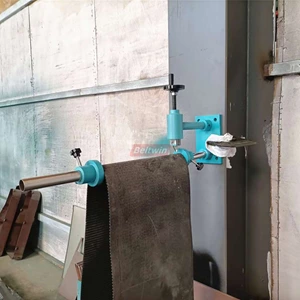

| Soporte móvil | Sin límite de longitud del cinturón |

English

English Русский

Русский Deutsch

Deutsch Français

Français Português

Português